Stingray Industrial Parts Washers

StingRay Build Quality & Applications

What Makes A StingRay Heavy Duty?

- Designed to Last, a StingRay Parts Washer is fully Engineered for Structural Integrity. Structural Engineers studied every load carrying component and over-designed each component for maximum strength and stiffness to provide the utmost value.

- High Turntable Load Capacities – StingRay turntable loads capacities are some of the highest in the industry. Not all load capacities are the same. Off-center loads create bending moment and torque that greatly affect the rating of a turntable. Without knowing the bending moment capacity of the turntable the static load capacity at the center has little meaning.

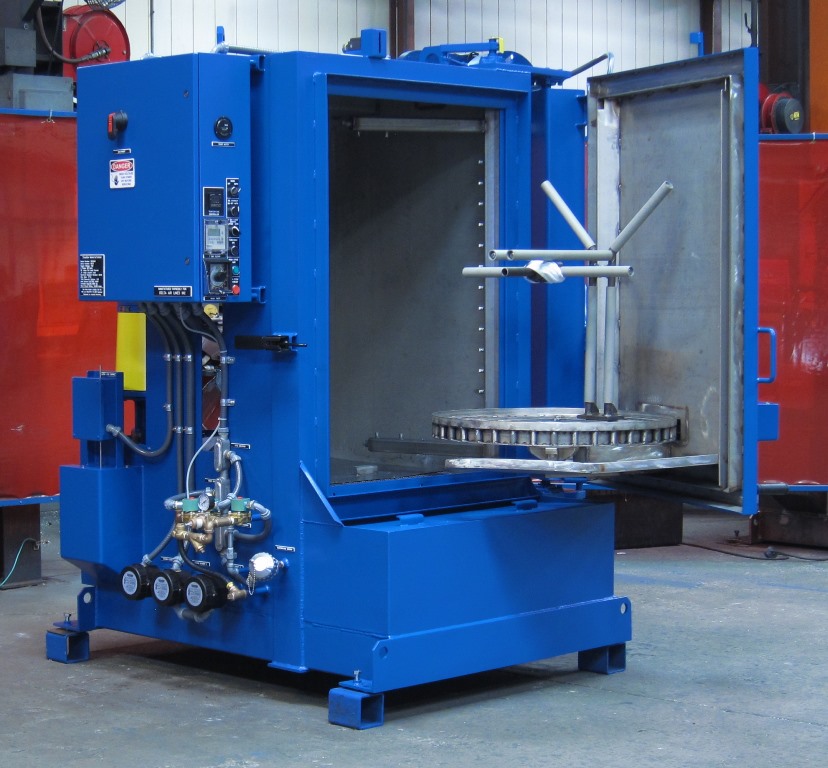

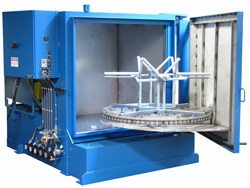

- Oscillating Manifold – StingRay non-synchronized moving wash manifold blasts your parts from multiple angles during the cleaning process far exceeding the results from fixed spray angle systems common in many parts washers. It is built from ¼’ carbon steel square tubing and ASTM rated pipe. The manifold is oscillated by a ruggedly engineered drive assembly and fully machined sealed swivel joint to allow it to move freely during operation. This system is field proven for reliability.

- Power Density – The StingRay combination of work volume, horsepower and high efficiency pump systems allow the user to clean even the largest parts. StingRay offers the widest selection of power density upgrades available on the market today. StingRay pump frames and support structure are engineered for 150 hp, three times the rated horsepower applied to any structure. While other washers just get your parts wet, StingRay utilizes high performance pumps to blast your parts clean.

- High Efficiency Eclipse Burner & High Output Electric Heating – Equally as important as the power density is the heat available during the cleaning process. StingRay engineers each parts washer to insure that it will maintain temperatures of 160 – 195 degrees during your heaviest daily cleaning.

- Materials of Construction – ASTM structural materials for all load carrying members and structures. All structural angles, box beams and wide flange I-beams meet ASTM A36 requirements. Cabinets construction is 7 gauge sheet and 3 gauge plate which is ASTM specified for known capabilities and verified structural integrity. StingRay does not use any off spec structural materials or materials from auctions or unknown sources. All materials have certified ASTM specifications.

- Welding – performed by certified welders to AWS weld specifications using certified welding materials and techniques. All welds are visually inspected to StingRay and AWS welding standards for assurance of maximum strength. Water tight welds are leak tested mechanically.

- Structurally Rugged Turntable – is built from solid steel rolled rings, rugged steel webbing and solid steel pins to drive your largest load. The webbing is full penetration welded to the support shaft or hub for maximum rigidity and stiffness.

- Over-Engineered tested door frame, base frame structure and turntable support – with a minimum design factor of safety of 3. All base and door frame structural steel angle meets or exceeds the ASTM –A36 requirements.

Applications

- Military Applications

- Aircraft Wheel Parts Washer

- Aircraft Brake Parts Washer

- Aircraft Bearing Parts Washer

- Transmission Parts Washer

- Electric Motor Parts Washer

- Diesel Engine Block Parts Washer

- Caterpillar Diesel Engine Parts Washer

- Large Parts Washer

- Rail Bearing Parts Washer

- Locomotive Crankcase Washer

- Steel Mill Bearing Parts Washer

- Wind Turbine Gearbox Parts Washe

- Paint Stripping and Paint Removal

- Tree Sap, Pitch & Resin Removal

- Ink Pail & Ink Tote Parts Washer

- Cosmoline Removal

- Dykem Removal

- Wastewater Evaporatio

- Wastewater Processing

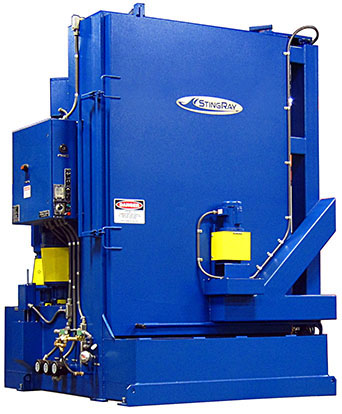

Retractable Turntable Parts Washers

StingRay Retractable Parts Washers are perfect for a wide variety of industrial aqueous cleaning applications. The smaller models were designed for the washing of automotive, transmission, and diesel engine parts and components. Larger models are used for parts washing by electrical motor rebuilders, wheel shops, diesel engine rebuilders and the US military. These parts washers excel in applications where the cleaning power of the innovative StingRay washing pump can truly be utilized to remove some of the toughest industrial dirt and grime.

StingRay 3040

The StingRay 3040 industrial parts washer is engineered for cleaning automotive engines, transmissions, electrical motors, bearings and other components. The StingRay 3040 Parts Washer can prewash a complete engine prior to rebuild.

The high power density and high temperature aqueous wash cycle makes it popular for cleaning gasoline engine heads and engine component parts plus aircraft bearings for recycling. It is perfect for new manufacturing applications where work cells need a closed loop parts washer that can wash, fresh water rinse, apply rust inhibitor and dry parts without discharging solution in the work area.

StingRay 3055

The StingRay 3055 Aqueous Parts Cleaning machine is engineered for cleaning engines, transmissions, and components in automotive shops. The StingRay 3055 Parts Washer can pre-wash a complete engine prior to remanufacture in less than 6 minutes. The high parts cleaning power makes it popular for cleaning engine heads and components and electric motors and bearings for rebuilding.

The SR3055 parts washer is perfect for new manufacturing cleaning applications where work cells need a closed loop industrial parts washer that can wash, fresh water rinse and apply Rust Inhibitor without discharging solution in the work area.

StingRay 4040

The StingRay 4040 Aqueous Parts Washer is engineered for cleaning over-road truck transmission and carrier rebuilders. The versatile design of the StingRay 4040 provides excellent cleaning power and short wash cycles for heavy duty soils.

This industrial parts washer is very popular for cleaning and degreasing engines and transmissions in truck component and off-road rebuilders like Caterpillar and Komatsu, as well as many rail shops for brake and power pack rebuilding. It is also available with an extended 63″ work height for washing taller parts.

StingRay 4063

The StingRay 4063 Parts Washer is one of the most popular models because of the Hi-profile work area. Engineered for washing Komatsu and Caterpillar off-road equipment’s mid-sized diesel engines prior to rebuild.

It’s also a perfect fit for degreasing rail bearings, electric motors and many other industrial parts cleaning applications that utilize the correct parts washer power density and oscillating power wash manifold offered in the 4063 Parts Washer. StingRay can also lengthen the work height for washing taller parts to fit your parts cleaning needs.

StingRay 5248

The StingRay 5248 aqueous parts washer is engineered for tough cleaning applications. The large heavy duty 52″ diameter turntable machine is heavy duty and features high parts washer power density for removing paint, oil, grease, hydrocarbon deposits and more.

Used in rail, over the road and off road rebuilding of engines, transmissions and associated parts. Automated aqueous parts washer utilizes unique oscillating spray manifold and high pressure to overpower the soils.

StingRay 5275

The StingRay 5275 industrial parts washer is engineered for tough aqueous cleaning applications. The large 52 inch diameter turntable and tall 75 inch working height allows easy & reliable cleaning for large parts. The 5275 parts washer uses high power density for fast wash cycles and high temperature operation for removing tough soils in short wash cycles.

Used in rail, over the road and off road rebuilding of engines, transmissions and associated parts. Automated cycle of the aqueous parts washer uses hydraulic force and the patented oscillating spray manifold to overpower tough soils. Other parts washing applications include electric motor cleaning and removing ink from totes.

StingRay 6048

The StingRay 6048 parts washer not only offers an impressive parts washer power density for parts cleaning but also the patented oscillating power wash manifold to maximize parts cleaning in any industrial application. These features make this industrial parts washer a must for any DC or AC electric motor rebuilder. It is also used by blenders of ink and paint to wash totes, tubs and pails thoroughly and cost effectively.

For tougher cleaning in larger diesel transmission, diesel engine and carrier rebuild shops the StingRay Parts Washer is equipped with high output electric heat or the gas/propane Eclipse burner system engineered to quickly remove carbon, grease, grime, paint and oil.

StingRay 6075

The StingRay 6075 parts washer not only offers an impressive parts washer power density for parts cleaning but also the patented oscillating power wash manifold to maximize parts cleaning in any industrial application.

It is the ideal industrial parts washer for off-road and over the road truck engines and transmissions, mining equipment engines, and marine engines. Additional industrial parts washing applications include the repair and rebuilding of marine thrusters & propulsors, gears, crankcases, heads and pumps.

StingRay 7266

he StingRay 7266 Parts Washer not only offers an impressive parts washer power density for industrial parts cleaning but also the patented oscillating power wash manifold to maximize parts cleaning in any industrial application.

Typical industrial parts cleaning applications include gear cases, drilling equipment, compression pumps and engines used in the oil field and natural gas industries.

HEAVY DUTY (HD) RETRACTABLE PARTS WASHERS

Engineered for cleaning larger components like Caterpillar engine blocks, locomotive traction motors and crankcases, ink totes, and jet engine components.

StingRay 60112

The StingRay 60112 aqueous parts washer offers an impressive work area, parts washer power density and impact pressure to wash larger Caterpillar engine blocks and EMD locomotive blowers. The oscillating power wash manifold removes the toughest soils eliminating secondary parts washing procedures.

Typical industrial parts washing applications include large diesel engine blocks and aircraft landing gear components.

StingRay 7273

The StingRay 7273 Parts Washer not only offers an impressive parts washer power density for parts cleaning but also the patented oscillating power wash manifold to maximize parts cleaning in any application.

It is ruggedly designed for aqueous parts washing in heavy industrial cleaning applications such as locomotive diesel engine and off-road diesel engine rebuilding and remanufacturing.

StingRay 8473

The StingRay 8473 industrial parts washer not only offers an impressive parts washer power density for parts cleaning but also the patented oscillating power wash manifold to maximize parts cleaning in any industrial application.

The large diameter turntable and high load capacity of this heavy duty parts washer is ideal for cleaning diesel engine blocks, wind turbine gear drives and power transmission, large industrial pump bodies and aerospace landing gear components. The StingRay 8473 parts washer is also used in the US nuclear industry.

StingRay 10073

The StingRay 10073 parts washer is engineered to provide the cleaning capacity to handle extremely large industrial parts cleaning loads. The impressive work area can even handle a complete Caterpillar 3516 engine in the horizontal position for pre-washing before tear down.

Additional industrial parts washing applications include cleaning gear drives & cases, precision gears, and torque arms from wind turbines, cranes, bridges, mining equipment and satellite antenna drives for rebuilding and repair.

Clamshell Parts Washers

Manufactured for applications beyond the capacity of the standard retractable turntable washer. The StingRay Clamshell washer is designed to handle loads up to 82,500 lbs and work heights matching your tallest parts cleaning requirement. Many standard features for this industrial washer line include our New Heavy-Duty 70 hp pump systems and sludge removal system to minimize maintenance. The v-notch roof line of the clamshell configuration offers easy access for loading with an overhead crane.

StingRay 84112

The StingRay 84112 parts washer is designed to clean large diesel engine blocks, locomotive crankcases or other dirty large parts. StingRay Parts Washer offers a total aqueous cleaning solution for large industrial applications.

The 84112 Clamshell industrial parts washer provides outstanding cleaning results through high wash power, high wash temperature, and its unique oscillating power wash manifold.

StingRay 10090

The StingRay 10090 Clamshell industrial parts washer is engineered for heavy duty parts cleaning in many different industrial applications when the part weight exceeds 20,000 lbs / 12,684 kg.

Applications include repair and rebuild of wind mill and wind turbine gearboxes, gear cases, precision gears, crane gear boxes, diesel engines, generators and surface mining equipment . The clamshell design provides complete access for loading and unloading parts weighing up to 60,000 lbs / 27,180 kg. Fast, highly reliable and unsurpassed cleaning capability is the StingRay parts washer trademark.

StingRay 12090

The StingRay 12090 Clamshell parts washer is engineered for heavy duty cleaning in many different applications where the load capacities exceed 20,000 lbs / 12,684 kg such as off-road equipment, surface mining electric and diesel shovels, loaders and steel mill component rebuilding and repair. =

The clamshell design provides complete access for loading and unloading industrial parts up to 60,000 lbs / 27,180 kg. The 12090 parts washer is unmatched in its high reliability, superior performance and productivity.

StingRay 13648

The StingRay 12090 Clamshell parts washer is engineered for heavy duty cleaning in many different applications where the load capacities exceed 20,000 lbs / 12,684 kg such as off-road equipment, surface mining electric and diesel shovels, loaders and steel mill component rebuilding and repair.

The clamshell design provides complete access for loading and unloading industrial parts up to 60,000 lbs / 27,180 kg. The 12090 parts washer is unmatched in its high reliability, superior performance and productivity.

StingRay 15060

The 15060 Large Clamshell Parts Washer is engineered for Heavy Duty cleaning in many different applications such as engine crankcase, gas turbine cases, off-road equipment, mining shovels and steel mill choke rebuilding.

The clamshell design provides you complete access for loading and unloading parts up to 80,000 lbs / 36,400 kg. Large industrial parts washer built for rugged parts cleaning in tough environments.

In Line Parts Washers

Engineered for large volume parts washing, this washer is fully automated and designed into your process. It is a favorite for washing rail bearings. Depending on your part washing demand we can include any of our automated conveyor systems and fixturing.

StingRay 6048

The StingRay 6048 Inline Dual Lift Door Parts Washer not only offers an impressive parts washer power density for parts cleaning but also the patented oscillating power wash manifold to maximize parts cleaning in any industrial application. The parts washer is designed for conveyor feed for maximum throughput in automated parts cleaning process lines such as in the cleaning of rail bearings for reconditioning and rebuild.

The parts washer is designed to automatically clean a standardized pallet load of parts. Dual entrance and exit lift doors automatically open for loading and unloading of parts. Turntable roller tracks are designed to receive a standardized pallet with a basket or a fixture load of parts, the track rollers mate with feed and discharge rollers located outside cabinet. The machine locks the standard pallet loaded with parts onto the turntable for cleaning.

StingRay offers various levels of automation depending on the needs of the end user. Powered entrance and exit conveyors are available for feed and discharge of the wash load. An automatic loading device that moves pallets from the entrance conveyor onto the turntable is available as an option. Full automation is available whereby pallet loads queued at the entrance conveyor are automatically processed through the escapement mechanism, cleaned and discharged without operator intervention.

Aircraft Wheel Washer Systems

Engineered to clean aircraft wheels of all sizes in quick cycles, these parts washers feature complete cleaning system with high power density that remove rubber bead without brushes and produces clean and dry wheels in under 15 minutes. Used throughout the aviation industry for washing wheels as well as aircraft brakes. Stainless Steel construction for long economic life.

StingRay 3032

The StingRay 3032 Aircraft Wheel Washer, cleans wheels, bearings and brakes in one machine. The turntable space cleans one wheel half at a time in short cleaning cycles. The washer power density and the patented oscillating power wash manifold removes rubber bead, carbon dust, grease, oil and soils from Aircraft wheels without brushes.

Use the automatic cleaning cycle to wash, rinse and dry aerospace wheels, bearings and brakes. It produces four to six clean and dry aircraft wheel halves in a closed loop cycle every hour. For more details please visit the case studies on Aircraft Wheel Cleaning in the parts washer applications section.

StingRay 4036

The StingRay 4036 Aircraft Wheel Washer provides high parts washer power density and the unique oscillating power wash manifold to thoroughly remove rubber bead, carbon dust, grease, oil and soils in quick cycles from Aircraft Wheels. Working closely with the US military and other end users in the airline and aerospace industry, StingRay Engineering developed this wheel cleaning system for washing aircraft wheels for inspection and rebuild.

The StingRay 4036 parts washer features a fully automatic cleaning cycle with wash, rinse and dry cycles for aerospace wheels and aircraft brakes. The wheel washer system yields four to six clean and dry aircraft wheel halves in a closed loop cycle per hour. Additional details are available in the case study on Aircraft Wheel Cleaning in the parts washer applications section.

StingRay 6036

The StingRay 6036 Aircraft Wheel Washer offers the necessary parts washer power density and the patented oscillating power wash manifold to quickly and thoroughly clean Aircraft Wheels of rubber bead, carbon dust, grease, oil and soils. StingRay Engineering worked closely with the US military and many users in the airline and aerospace industry to develop this high efficiency method for cleaning aircraft wheels.

The StingRay 6036 parts washer runs an automatic cleaning cycle to wash, rinse and dry aerospace wheels and aircraft brakes. It produces eight to twelve dry aircraft wheel halves in a closed loop cycle every hour. For more details please visit the case studies on Aircraft Wheel Cleaning in the parts washer applications section.

Stingray Videos

Ultrasonic Cylinder Head Cleaning

StingRay Parts Washer Power Blast Manifold

StingRay Parts Washer Fresh water Rinse Closed Loop

Stingray Parts Washer Flash Drying

StingRay Parts Washer SR13648 CAT C175 Block

StingRay Parts Washer for Rail Bearing Cleaning