Machine Operations

- Seat & Guide Machining

Product Details

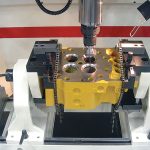

The Rottler SG90A (previously SG80A) was created specifically for machine shops that rebuild small to large cylinder heads found in the heavy duty engine industry. Large cylinder heads come in many shapes and sizes, from 24 valve single casting cylinder heads to huge single cylinder heads used in natural gas, mining and marine workboat engines. We put our trusted engine block machining technology to work designing a heavy duty machine that handles many operations required on a wide variety of cylinder heads. At Rottler we believed that many large cylinder heads could be “plunge cut” with fixed tooling to save time and money. We realized that plunge cutting would require a very rigid machine utilizing many of our already established design features such as Rottler’s exclusive spindle design.Over the decades, Rottler’s spindle design has proven that our engine block machines are able to “plunge cut” wide counterbores found in large engine blocks with exceptional results. We used this spindle design for the SG90A and it has since been proven, in over 50 machines, that the SG90A is capable of plunge cutting large valve seats very quickly and with excellent CONCEN and surface finish

- Proven Rottler Spindle Design – The large diameter precision spindle nut has an R40 taper with the Quick Change Self Locking Spindle Nut System. Tooling never comes loose and no wrenches are required to change tools. Rottlers unique Heavy Duty tooling allows large and wide Valve Seats to be machined to accurate Concentricity. Solid Carbide Pilots offer maximum rigidity and long life for years of precision machine work.

- Touch Screen Control Technology – The SG90A features a Conversational Touch Screen Control that allows the operator to program the machine to cut at certain RPM with a specific feed rate. This eliminates chatter when cutting hard valve seats by eliminating the human error of the operator truing to feel the cutting action. See controls for more information.

- UNIPILOT Tooling – The UNIPILOT tooling system allows the carbide centralizing UNIPILOT to work like a live pilot. It stays in the spindle while moving from valve guide to valve guide, but all at the same time has a fixed pilot design to give improved concen. See brochure for more information.

- 360 Degree Roll Over Fixture – Rottler’s 360 Degree Roll Over Fixture comes standard on the SG90A. The fixture allows large 24 valve cylinder heads to be clamped with reference to their head gasket fire deck and rolled 360 degrees in one set up. The heavy duty clamping and fine adjust system allow quick leveling and rigid clamping for heavy cutting during machining. (Optional)

- Adjustable Air Float and Air Clamp Work Table – The large worktable of the SG90A consists of two 68″ (1730mm) long parallels that are mounted on an air floating and air clamping base. These extra long T-slot parallels allow a wide variety of fixtures and jobs to be set up for machining. The complete table and fixture assembly is easily adjusted in/out with air float and locked rigidly with air clamping allowing cylinder heads with four valves per cylinder to be adjusted in/out and machined without resetting of the cylinder head in the fixture. Just press the foot pedal to float the table, slide in or out and the table locks in position ready for machining.

- Computer Machine Control with Windows XP Operating System Pentium 4, 40Gb Hard Drive, 3 GHZ CPU. 56X CD ROM, 4 X USB2, Ethernet Networking and Internet Connection.

- Automatic Cycles for Seat Cutting, Housing Boring, Guide Drilling and Reaming, Thread Tapping

- Programming and Machine Operation thru 15″ (400mm) extra bright touch screen.

- Electronic Handwheel for manual operation in .001″ (.01mm) or .005″ (.125mm) increments per Handwheel Detent

- Precision Digital Readout, .0001″ (.002mm) Resolution

- Spindle Travel by Precision Ball Screw & AC Servo Motor – Infinitely Variable Vertical Movement – Z Axis – Up and Down – 10″ (254mm)

- Spindle Rotation by AC Servo Motor – Infinitely Variable to 1000 RPM

- Machine Workhead Floats on Air Cushion for Precision Centering controlled from the Touch Screen – Total Travel in In/Out Direction 2.5″ (678mm) and Left/Right Direction 42″ 1067mm

- Spindle Head Tilt – 10 Degrees to left and right

- Heavy Duty Spindle with Inner Precision Angular Contact Bearings supported in Adjustable Outer Bearings

- Automatic Spindle Adapter Locking and Quick Release System

- 360 Degree Roll Over Fixture with Safety Chains for Large Cylinder Heads

- 2 Degree Independent Tilt Fixtures and Over Head Clamp Arms for Extra Large Cylinder Heads

- Table Cross Slide operated by Foot Pedal with Air Float for Easy Adjustment for In/Out Positioning of the Fixture – Total Travel 6.5″ 170mm

Windows 7 CNC controlled Ball Screw spindle drive produces the most accurate seat concentricity in the industry. Cutting parameters are controlled by the computer and stored. Rough and finish RPM and feed rates with a finish dwell cycle of two revolutions. Seats are finished to exactly the same height. The pulse hand wheel allows the operator to feed in .001 and .0001 increments. The Windows based program allows the setting of individual head details such as manufacturer, seat cutter used, pilot used, rough and finish RPM and feed rates. Windows CNC Ball Screw Controlled Spindle

| SG90A Machine Specifications | American | Metric |

|---|---|---|

| Control | Automatic CNC | |

| Touch Screen | 12″ | 305mm |

| Spindle – Taper | R40 Quick Change with Automatic Lock Nut | |

| Spindle – Diameter | 3.75″ | 95mm |

| Spindle – Rotation Speed | 50 to 1000 RPM | |

| Spindle – Motor | 6 HP | 4.48 Kw |

| Valve Seat Diameter Range | 0.550″-8.25″ | 14-210mm |

| Valve Guide Diameter Range | 0.160″-1.5″ | 4-38mm |

| Cylinder Head Dimensions (with 360 degree rollover fixture) | 49L x 14W x 10H” | 1250L x 355W x 254Hmm |

| Cylinder Head Dimensions (with Parallels) | UnlimitedL x 16W x 17H” | UnlimitedL x 406W x 430Hmm |

| Spindle Travel/Stroke Vertical | 9.5″ | 240mm |

| Spindle Motor Torque Peak | lb/ft | 60Nm |

| Workhead Travel Horizontal – Airfloat/Airclamp | 44″ | 1120mm |

| Workhead Travel In/Out – Airfloat/Airclamp | 2.312″ | 58mm |

| Workhead Tilt (either side of vertical zero) | 10 Degrees | |

| Worktable Travel In/Out – Airfloat/Airclamp | 7.5″ | 190mm |

| Maximum Distance from Parallels to Spindle | 26″ | 660mm |

| Dimensions – Machine | 47D x 69W x 83″ H | 1194D x 1753W x 2108mm H |

| Dimensions – Shipping | 60D x 87W x 90″ H | 1524D x 2210W x 2286mm H |

| Machine Weight | 5000 lbs | 2273 kg |

| Electrical Requirements | 208-240V, 30A, 50/60Hz, 1Ph | |

| Air Requirements | 15 cfm @ 90 psi | 400 l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) | |